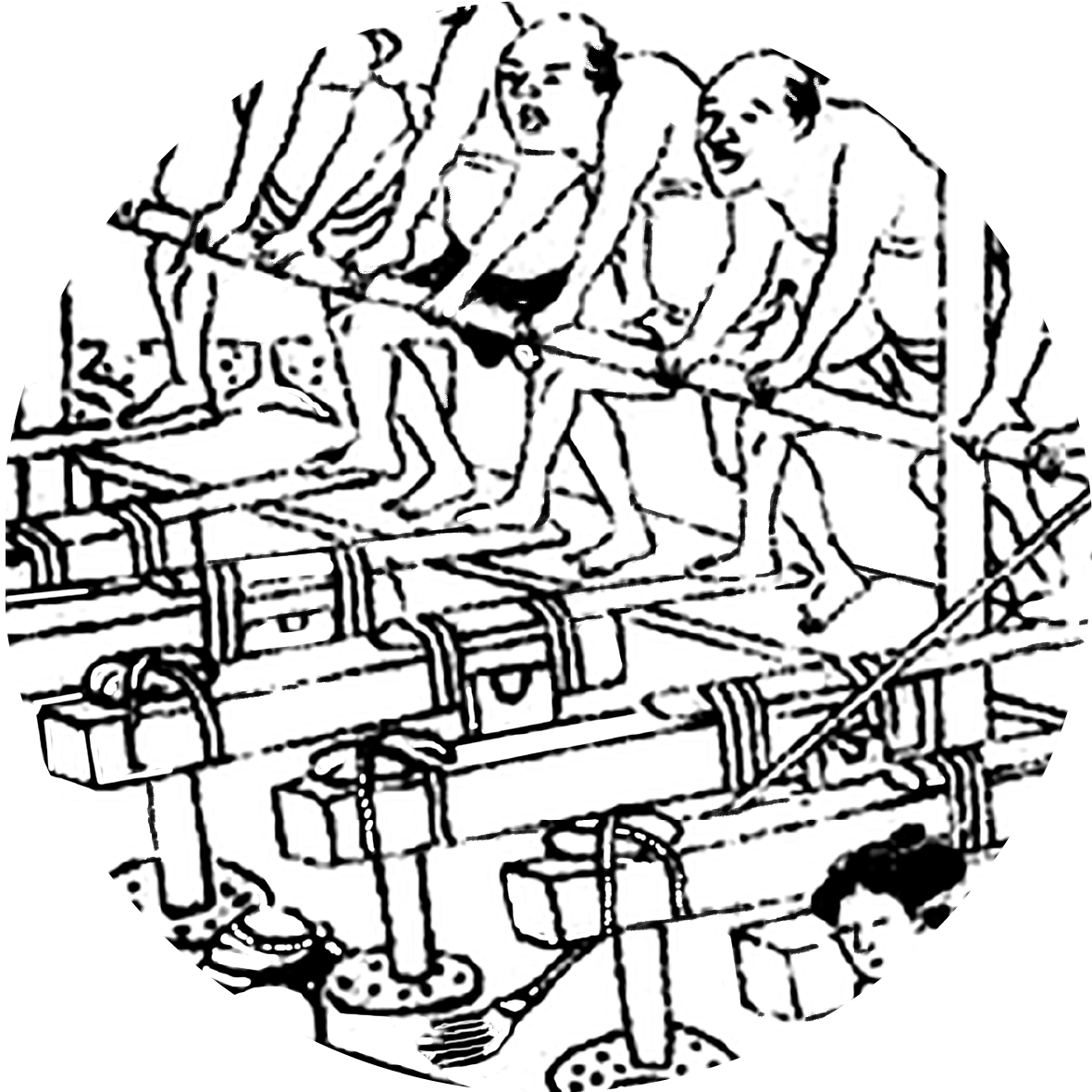

We adjust the rice polishing rate according to the quality of rice which varies every year. A chief sake maker, who knows everything about sake rice, carefully polishes selected Yamada-nishiki and Aiyama rices.

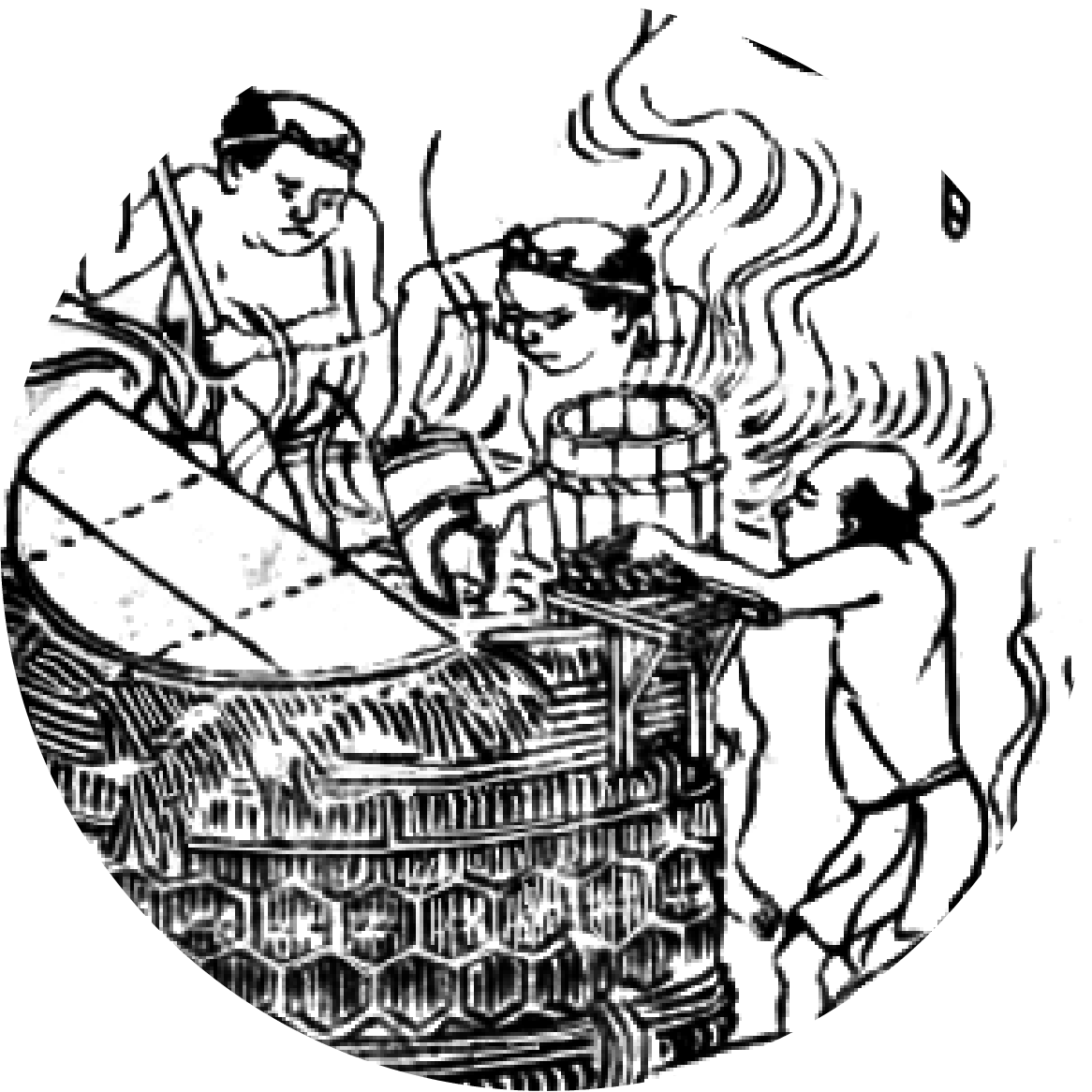

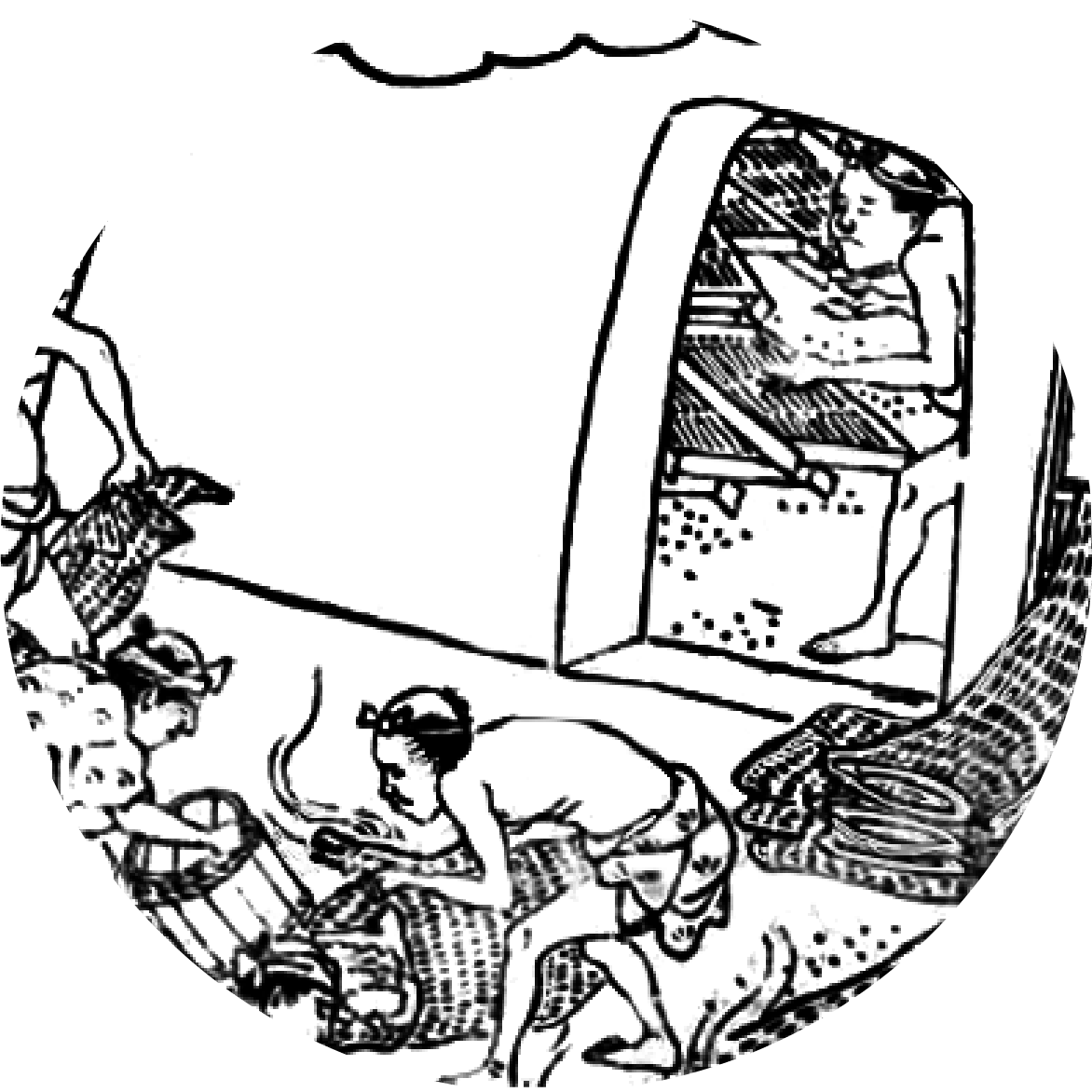

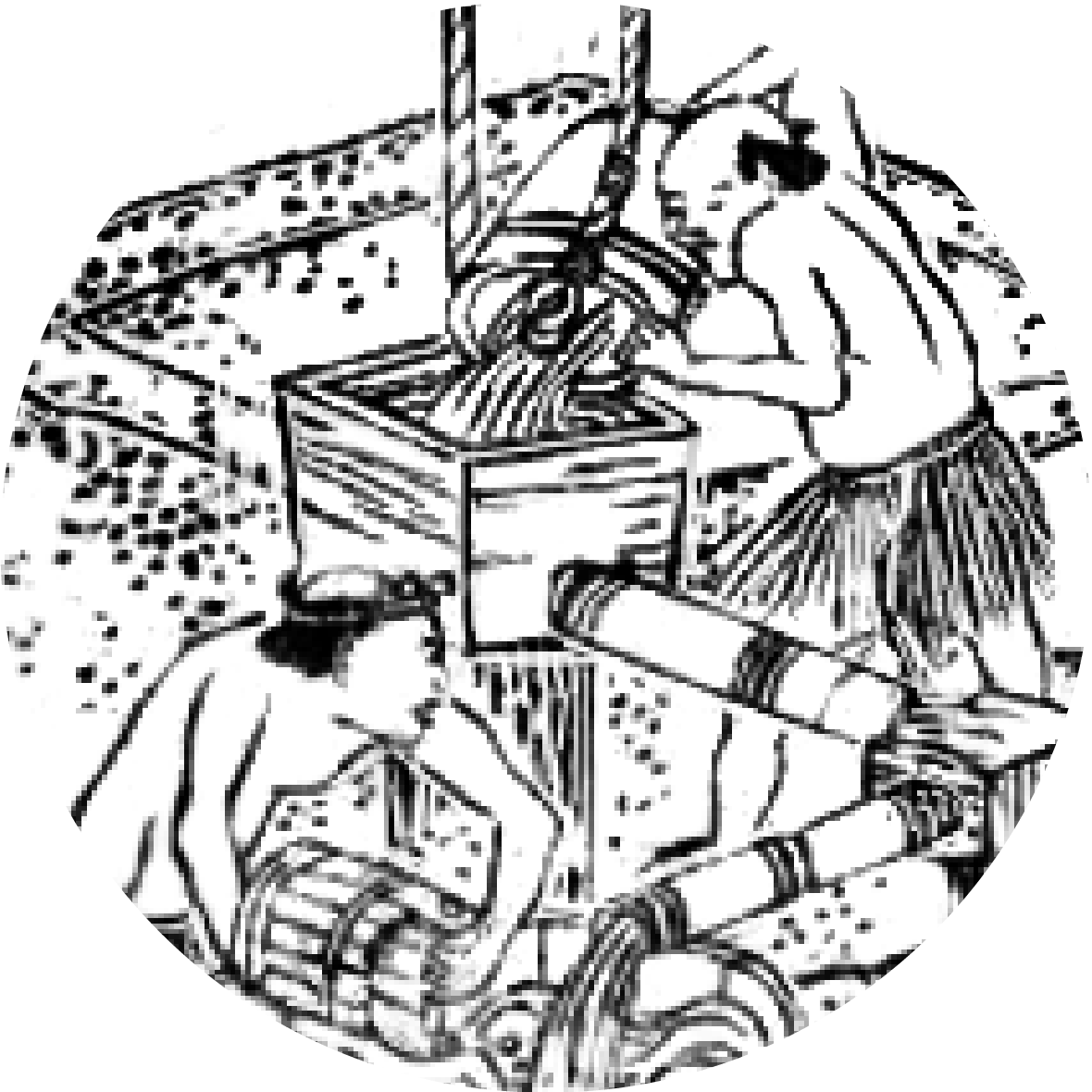

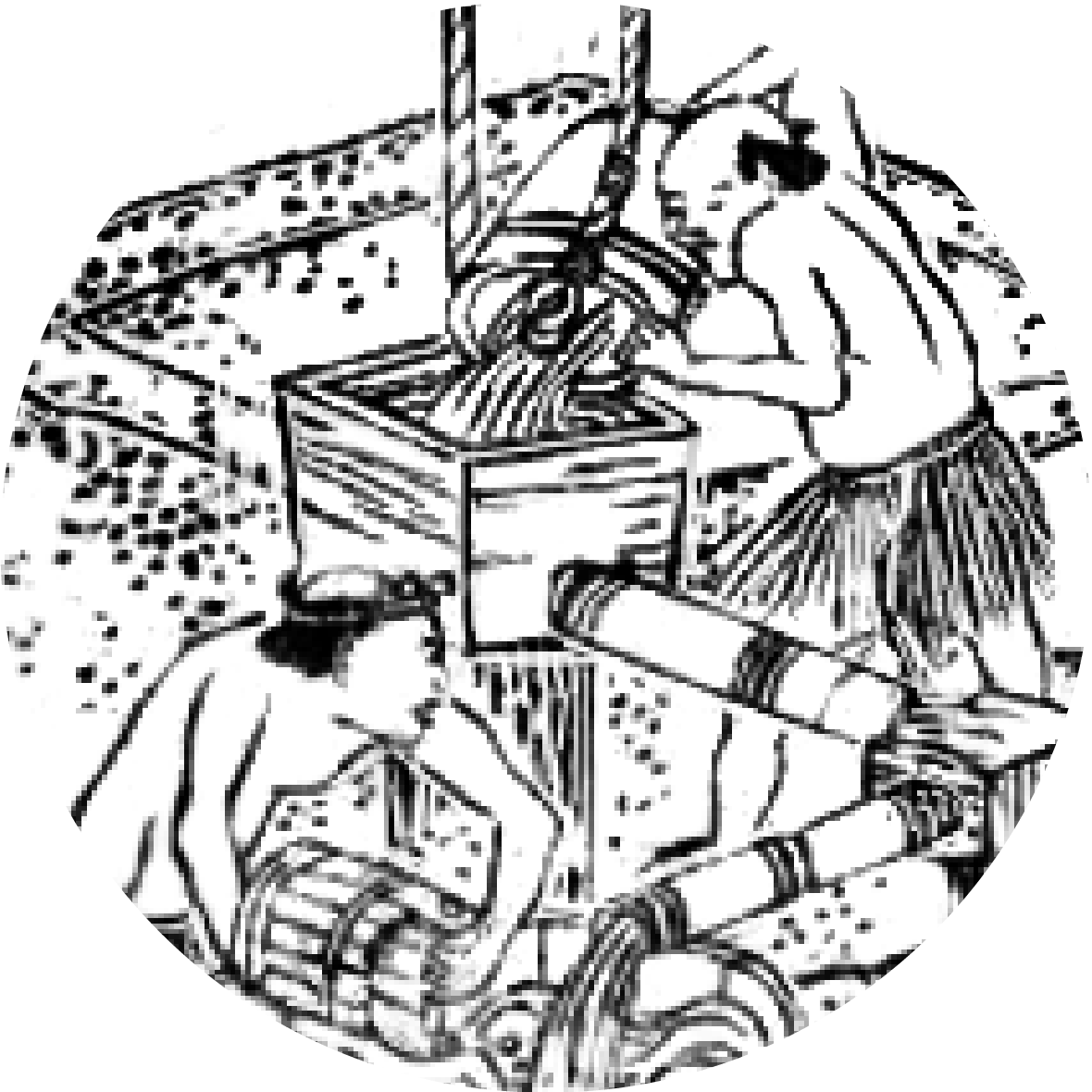

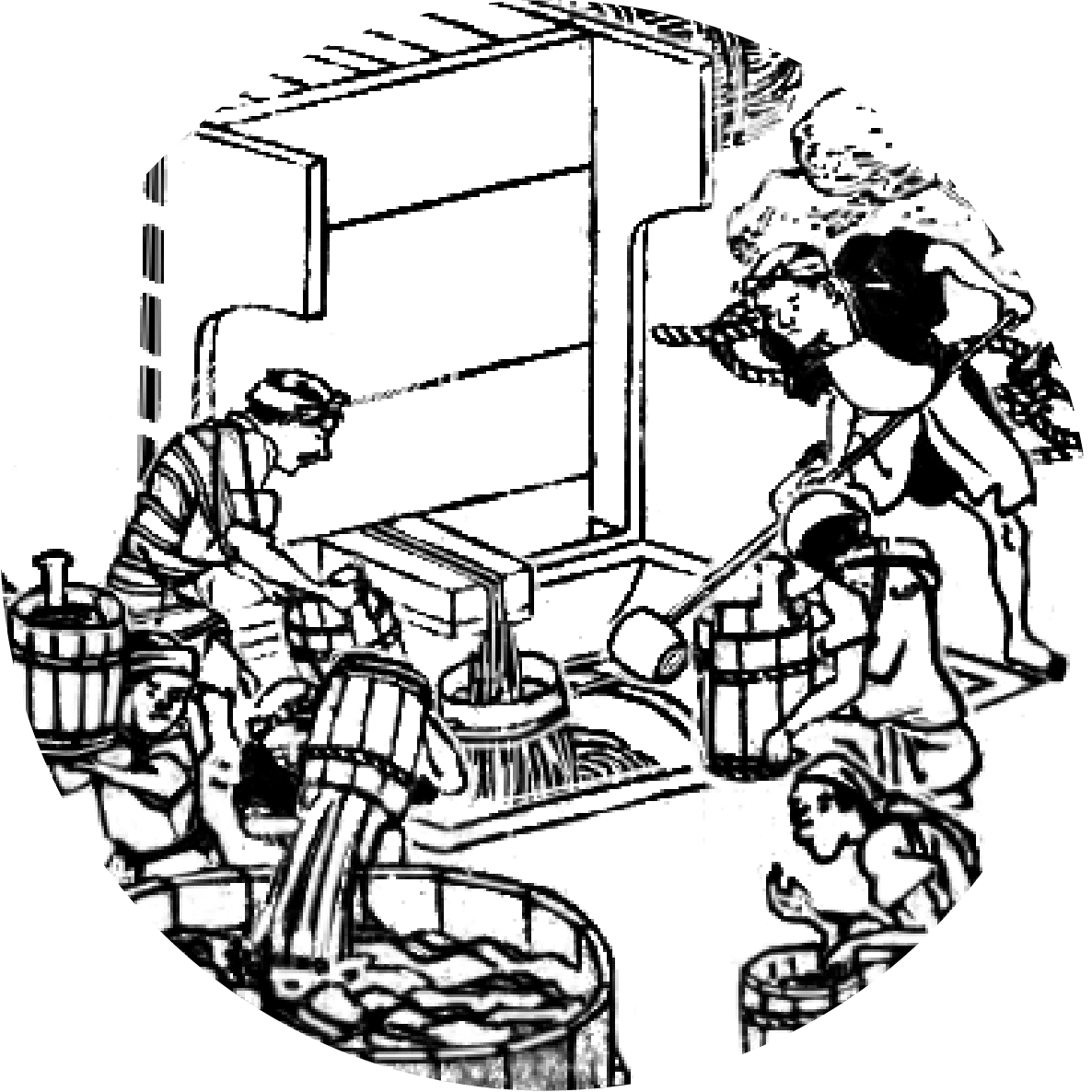

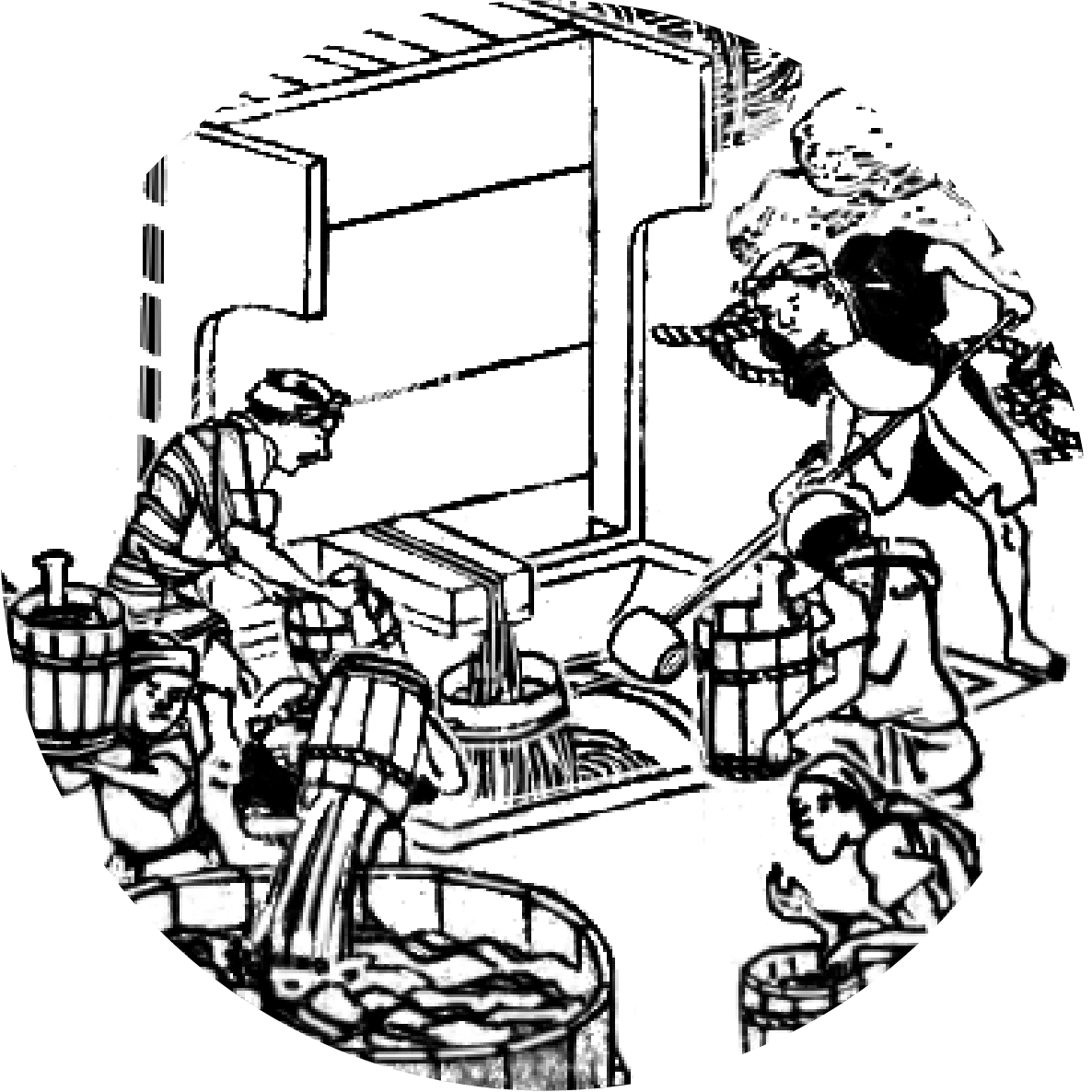

Rice is slowly steamed in a kama-pot using wooden utensils. The wood absorbs excess moisture, turning rice into the steamed rice with a quality desired by the producer.

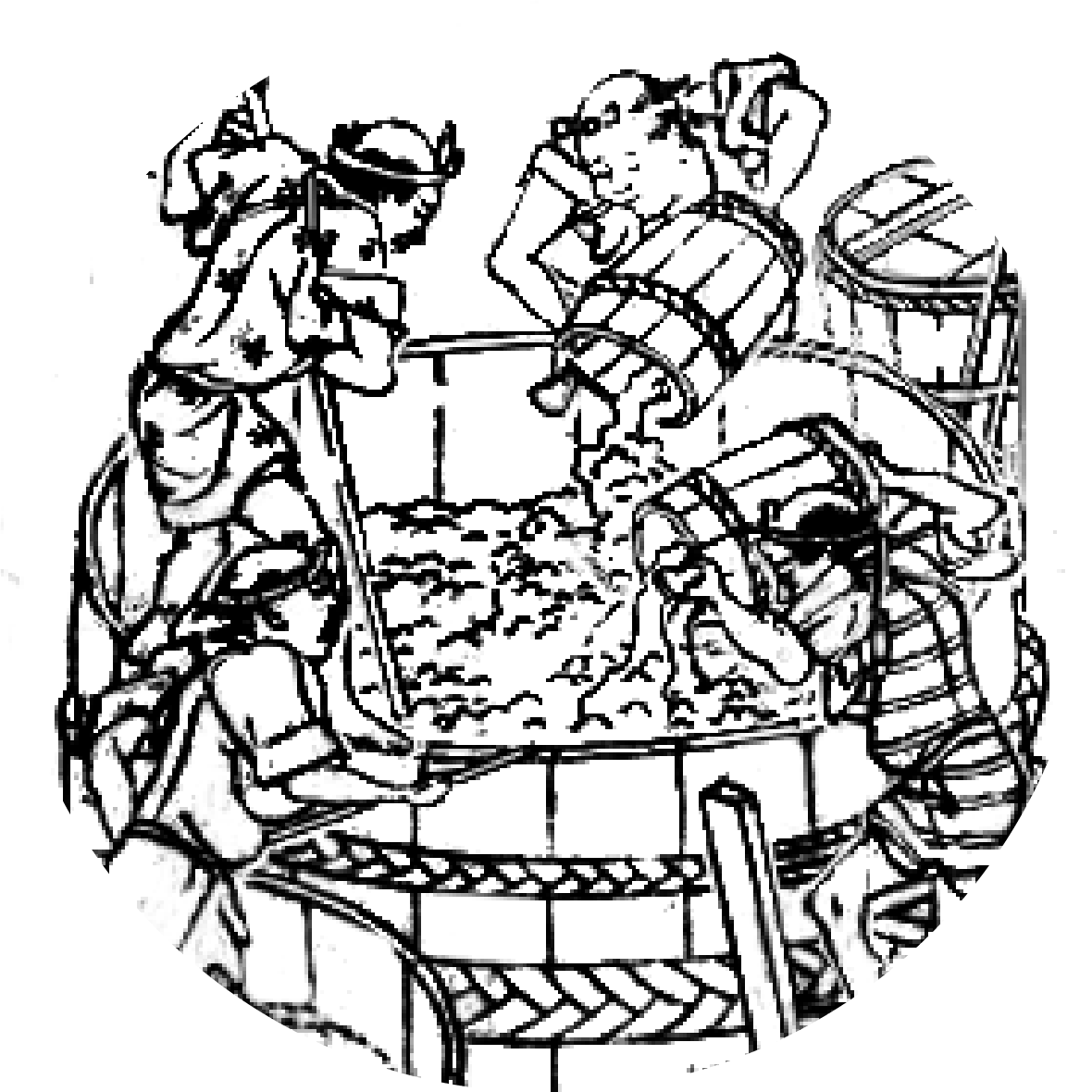

This is the most important and difficult process in sake brewing. Koji mold is grown into a powerful koji in the koji making room, which will be used to bring out the flavor of rice fully.

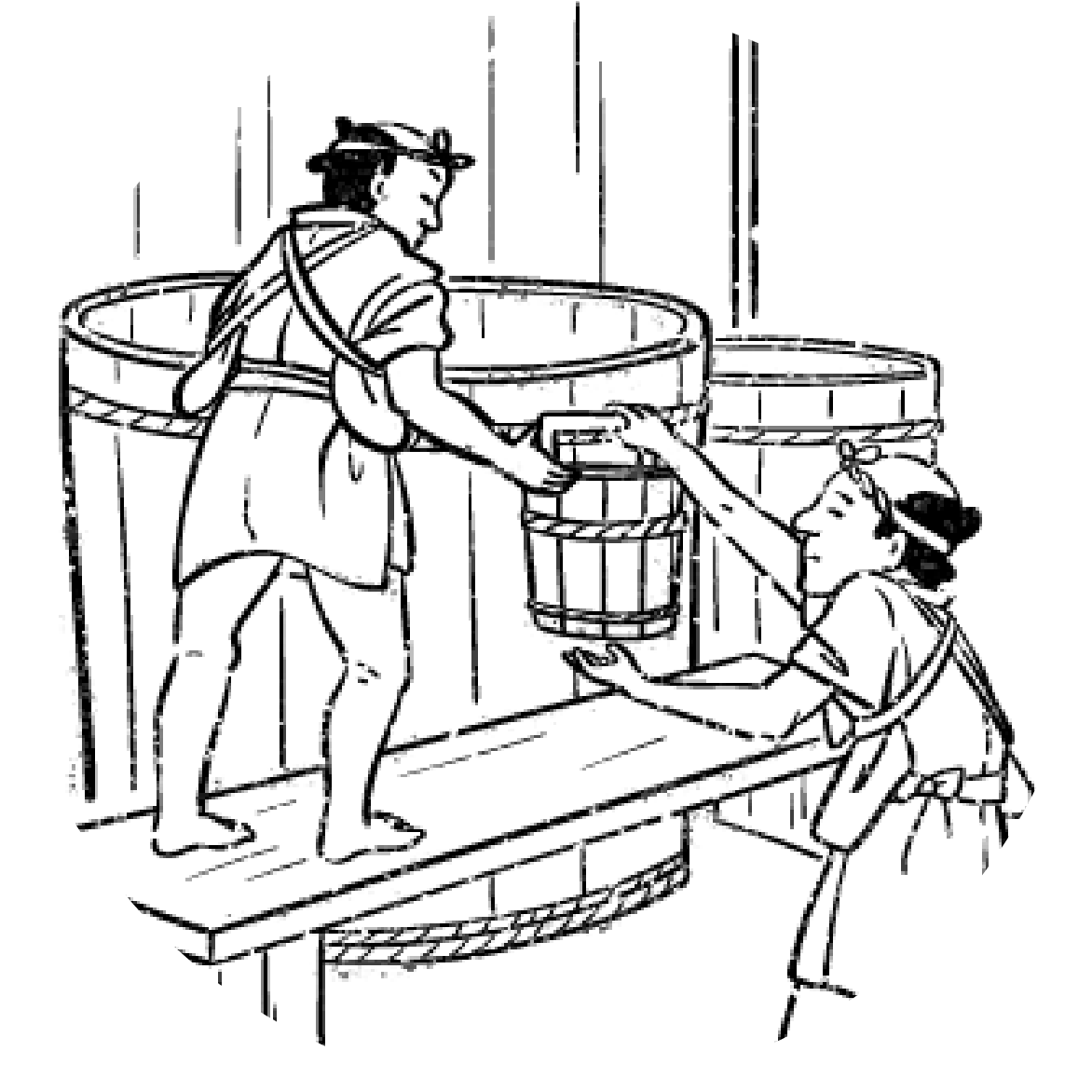

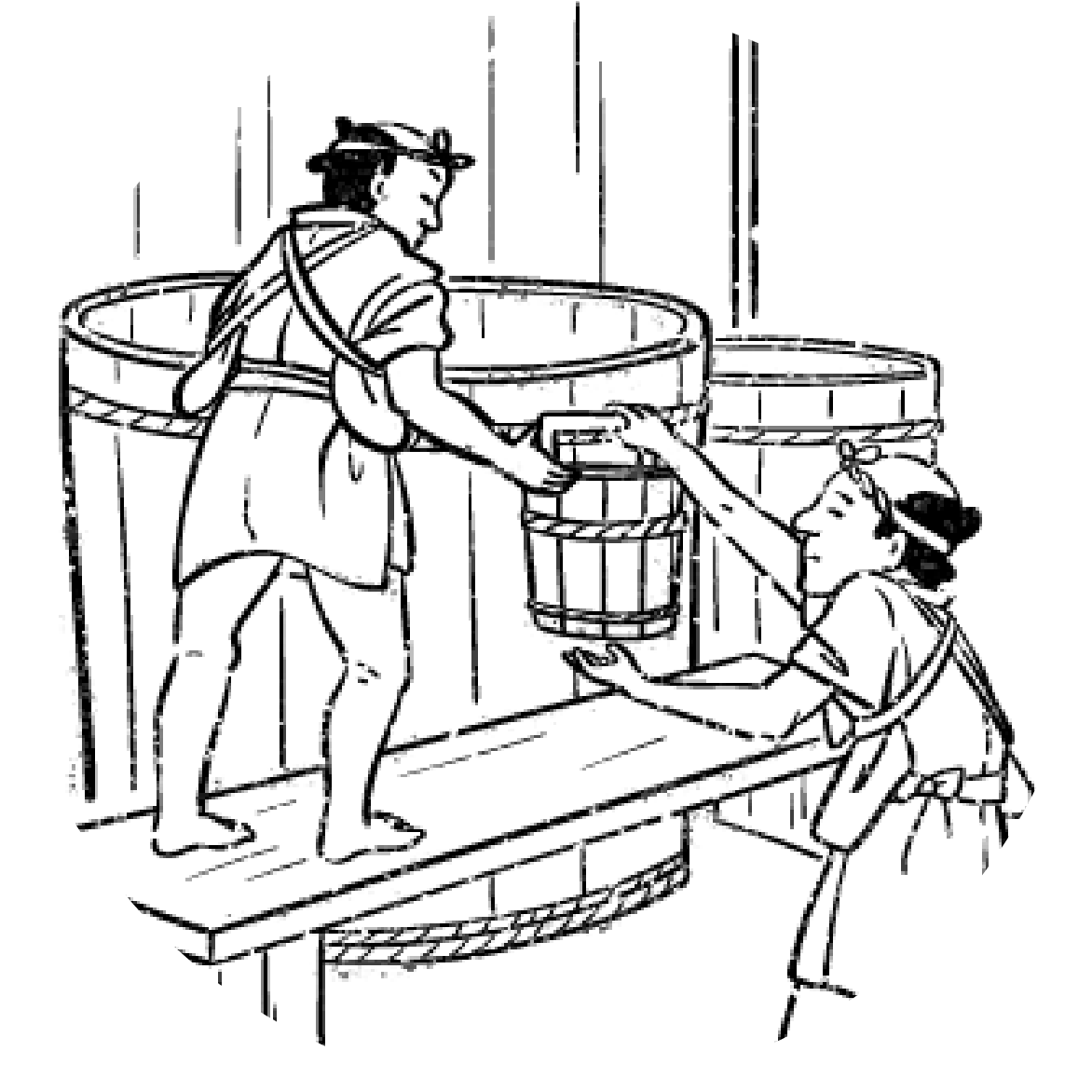

KENBISHI has inherited the traditional "YAMAHAI starer culture", in which yeast is purely cultured using natural lactic acid bacteria in the air. The use of yeast cultured in the brewery makes this process a crucial part of protecting our traditional taste.

Miyamizu is the water suitable for sake brewing. It has contributed in spreading the fame of "Sake of Nada" throughout the country. A lot about this water still remains mystery today, which is why it is also called "mysterious water".

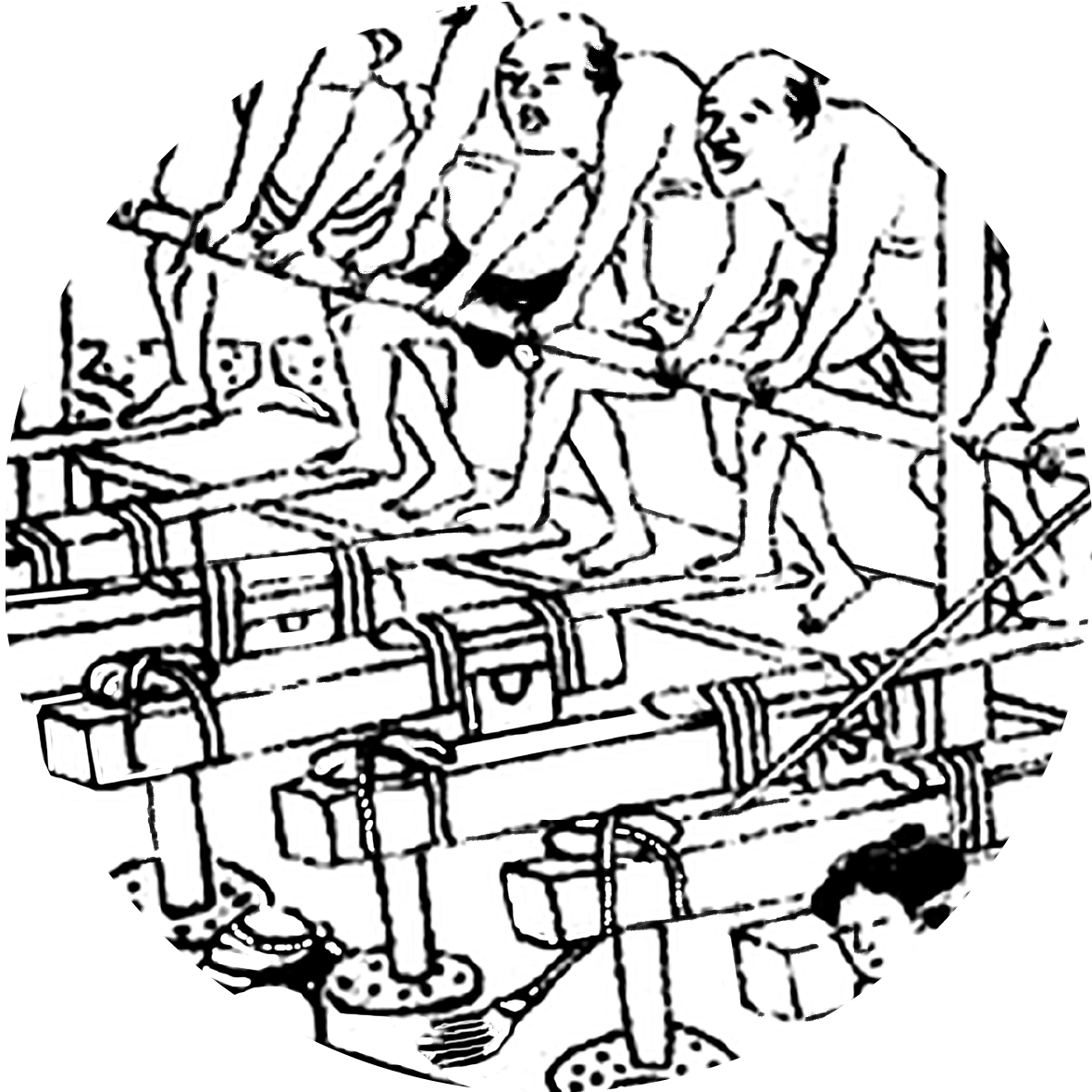

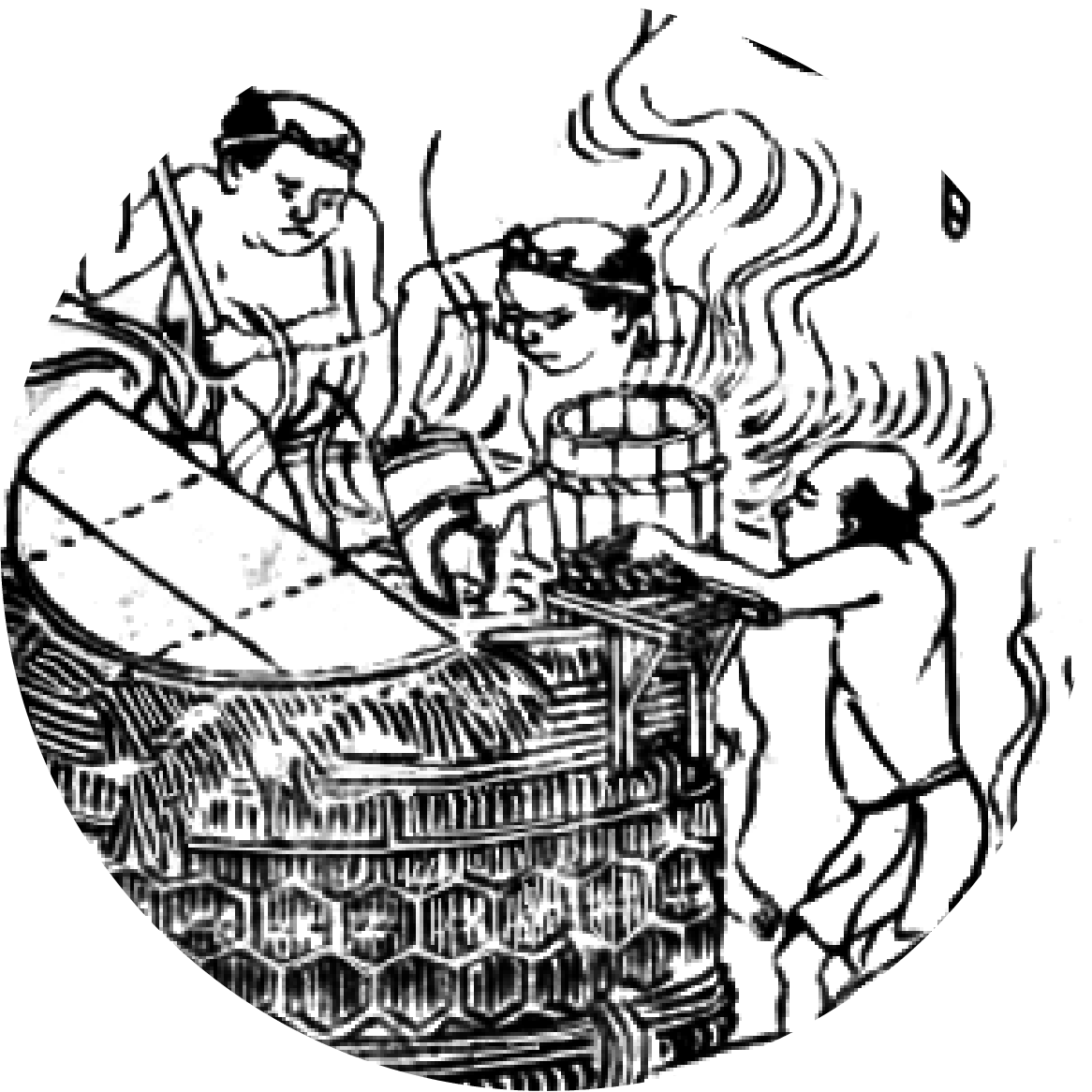

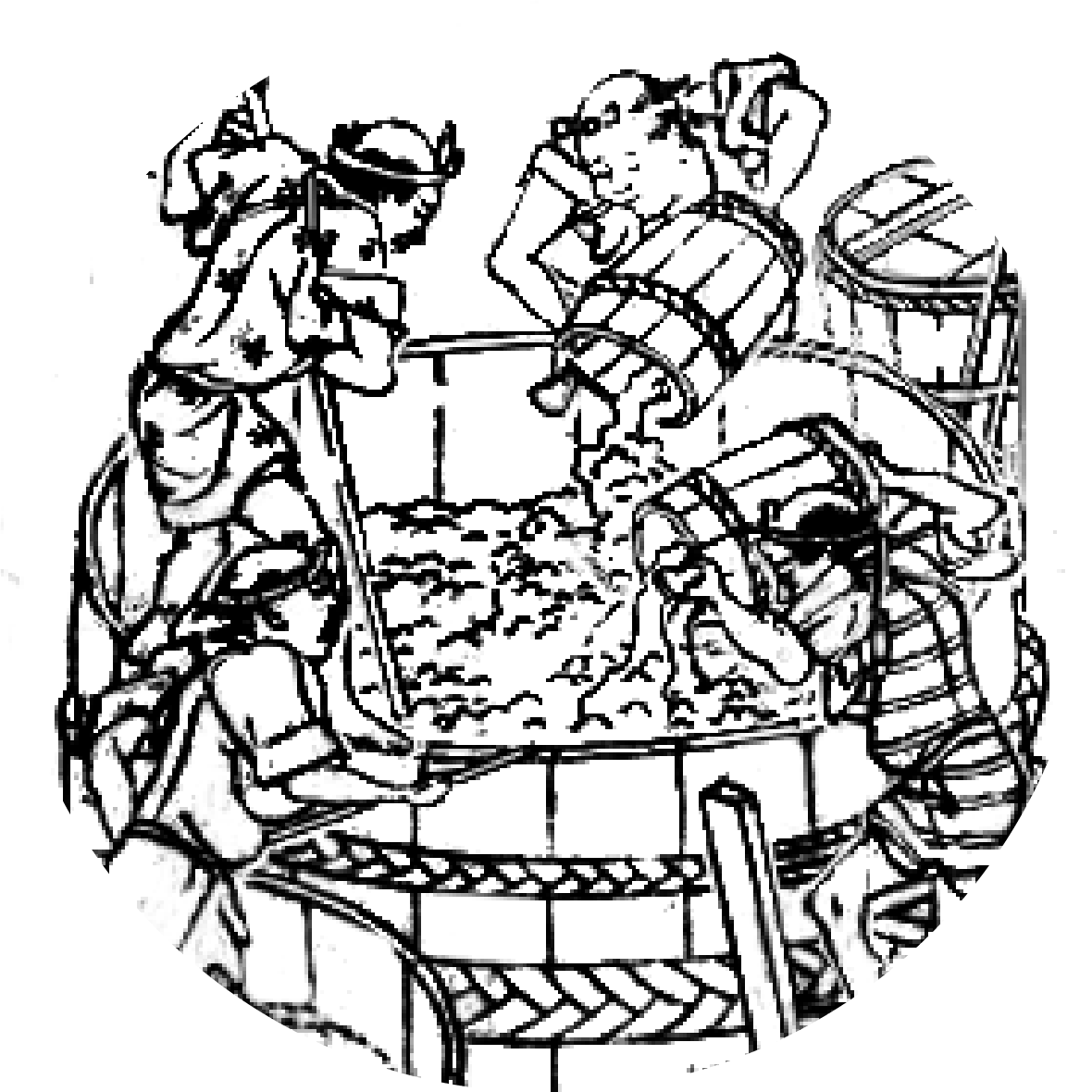

The mash is made by adding steamed rice, starter, koji, and Miyamizu. We wait for the mash to ferment while stirring with an old-fashioned wooden paddle. Powerful koji breaks down Yamada-nishiki, and yeast slowly turns it into sake.

The aged mash is separated into sake and sake lees. Rice has been fully broken down at this point, and the umami of rice is dissolved in the mash. By squeezing out the umami from the mash thoroughly, we create the depth and complexity in the product.

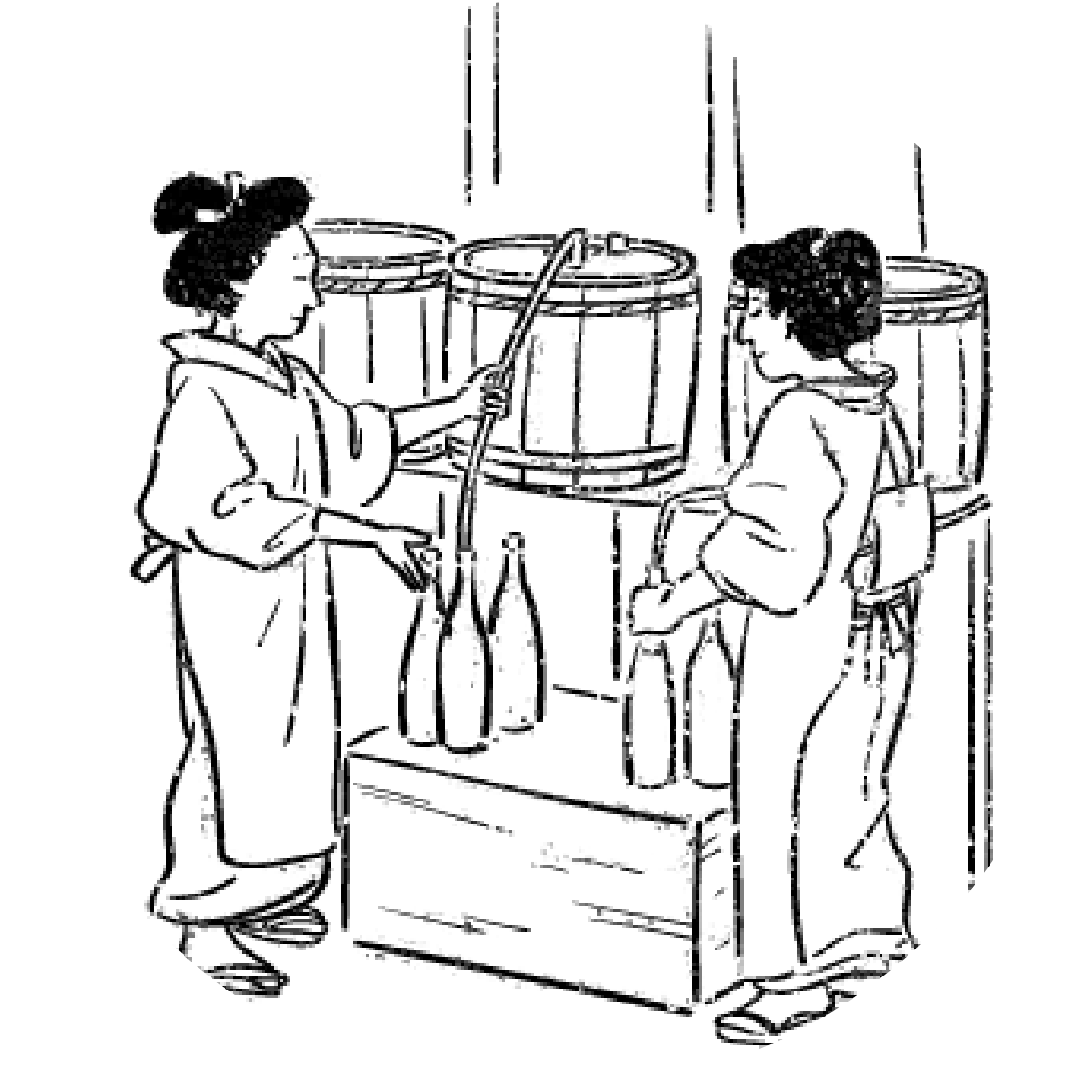

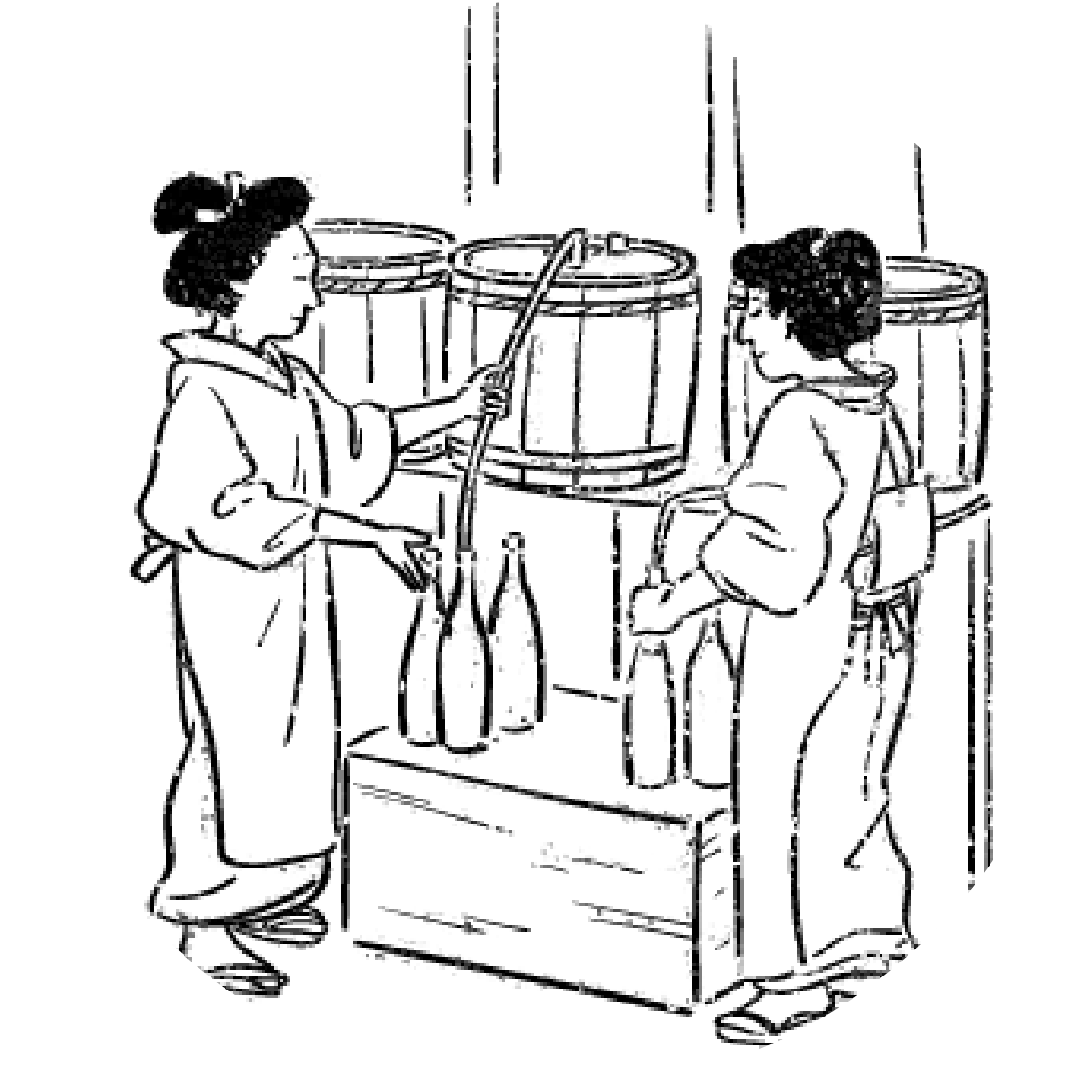

In addition to the taste check by "tasting sake", we also check for contamination and label defects. Products then go through final check by human eyes before being delivered to the customer.